About Atri-Press Hot Vulcanizing Press

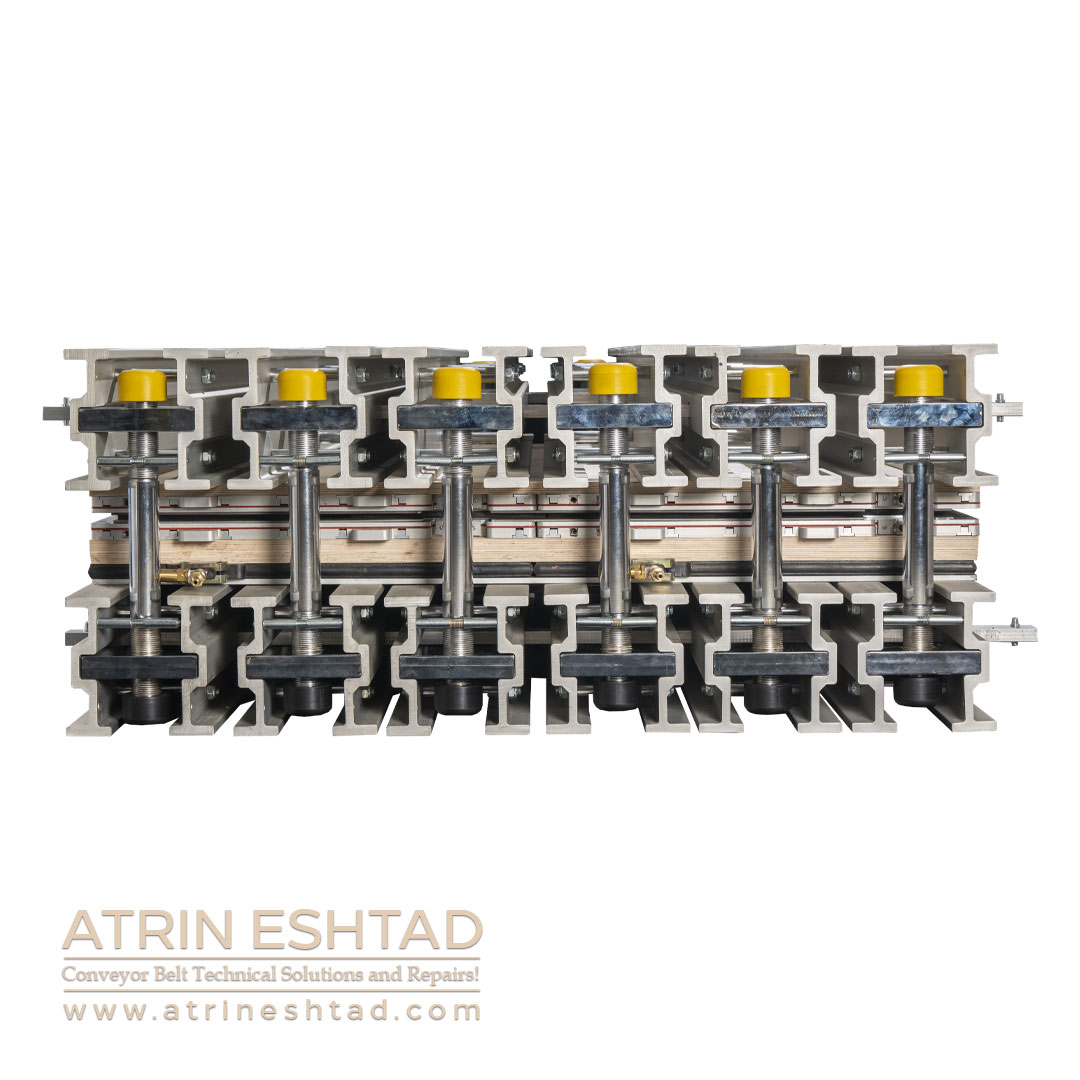

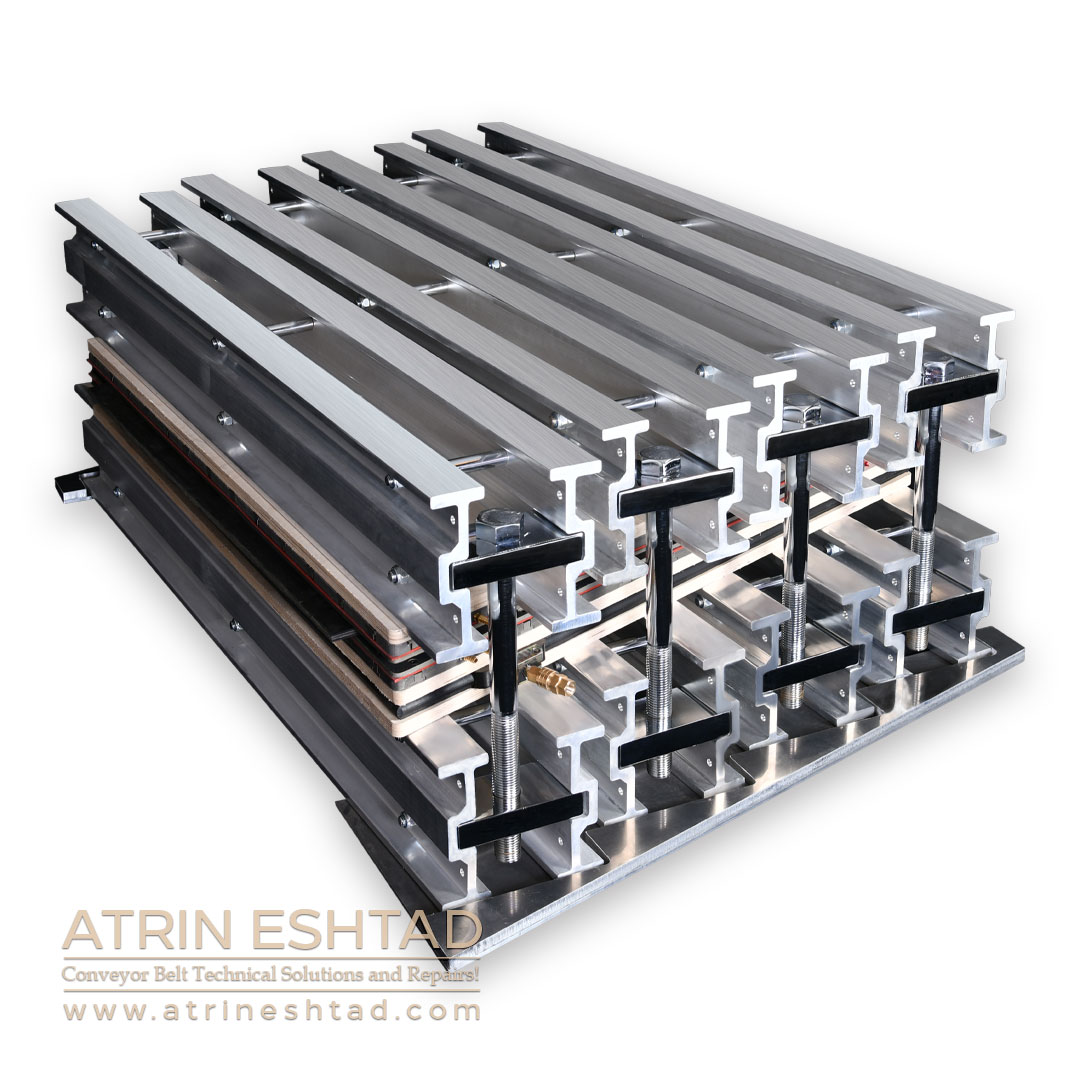

Atri-Press Hot Vulcanizing Press, manufactured by Atrin Eshtad Company, is the first and the only Iranian-made hot vulcanizing press. This machine has unique features such as integrated and automatic control box that can simultaneously control temperature, pressure and vulcanizing time. Reasonable price, valid warranty and easy access to customer services are the other features of Atri Press. It has also very light weighted design thanks to using special aluminum alloys and benefits from using high quality materials and equipments to extend the service life of the machine. With Atri Press you will have a uniform and homogeneous vulcanization on the entire splice area. It should be noted that Atri Press can be produced for conveyor belts up to 3000 mm wide.

Atri-Press Hot Vulcanizing Press Freatures:

- Uses high quality materials and equipment to extend the service life of the machine and lengthen the maintenance intervals

- Use of special aluminum alloys to reduce the weight of the machine

- Benefits from an integrated and automatic control box with the ability of precise and simultaneous control of temperature, pressure, and vulcanization time

- Increases the strength of the conveyor belt at the joint due to uniform and homogeneous vulcanization throughout the entire splice area

How to assemble Atri-Press Hot Vulcanizing Press

Here you can see the complete video of how to assemble Atrin Eshtad’s Atri Press 1000-900 Series

Technical Specifications:

Heating platens:

- Made of special aluminum alloys for decreasing the weight of the machine and improved heat transfer

- Accelerated process of reaching the vulcanization temperature compared to other models

- Equal and precise temperature distribution on the surface of both irons to increase the vulcanization quality

- Ceramic coating of the heating platen to prevent the conveyor belt from sticking to the irons and also electrical leakage

- Capability of adjusting and controlling the vulcanizing temperature up to 175 degrees

Traverse:

- Use of high-quality aluminum alloy for decreasing weight of Traverse bars with maximum potency

- Special design with unique profile to achieve maximum resistance to bending and deformation of Traverse bars

- Capability of endurance pressure up to 14 bar

Control box:

- Capability of automatic control of vulcanizing temperature, pressure and time.

- The ability to Provide diagrams to check the vulcanizing parameters

- Touchscreen monitor with easy to use and user-friendly functions.

- Shows the effective splice parameters on the display screen.

- having a Solid Case to protect sensitive equipment of the control box.

Other:

- The cooling system can be designed according to customer needs

- The splicing angle can be designed in various degrees (16.7, 22 and 90 degrees) according to customer needs.

- The power supply of the machine can be designed according to customer needs

There are no reviews yet.